The Sig Sauer P320 handgun is modular by design. The ability to swap calibers with different sized frames and slides provides a versatility that is driving a massive aftermarket for parts and accessories. Building a P320 is the perfect way to get exactly the gun you want without having to buy a new gun and throw away parts.

Even though Sig Sauer labors through the night, after over 1 million P320 pistols, demand continues to exceed production. The P320 has been selected by all branches of the U.S. military, the Department of Homeland Security, and many other military and law enforcement agencies around the world. What makes the P320 different from all the other striker fired guns out there?

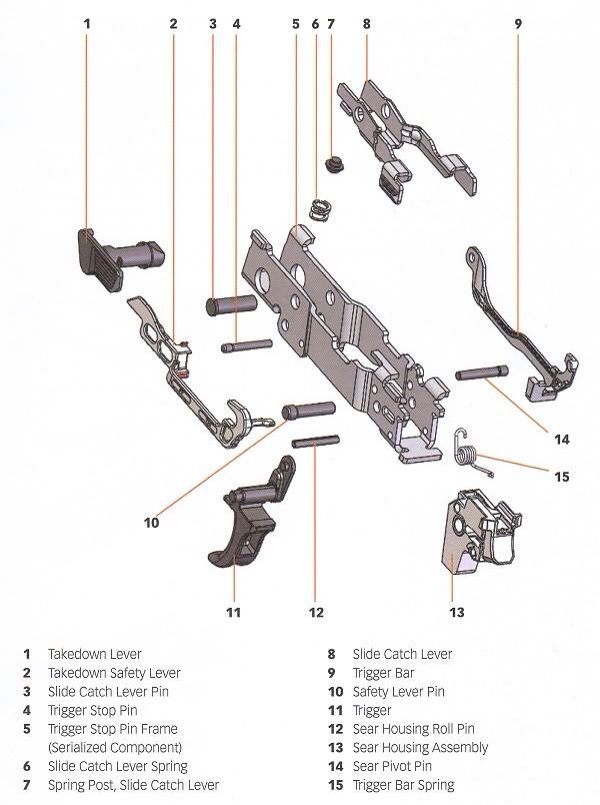

The unique feature of the P320 is the Fire Control Unit (FCU), a self-contained drop-in trigger box. The FCU can be dropped into subcompact, compact, carry or full-size kits including grip module, slide, barrel, recoil spring, and one magazine in 9mm, .357 Sig, .40 S&W, or .45 ACP.

NOTE: If you want a .45, the P320 can do it, but the grip modules and the Take Down Safety Lever are different. Not as easy to switch as the other calibers.

WARNING: Don’t take anything safety related on faith, do your own research. Always read the manual that came with your gun or accessory. If you add accessories, it is up to you to understand what you changed and how it will effect safety and performance.

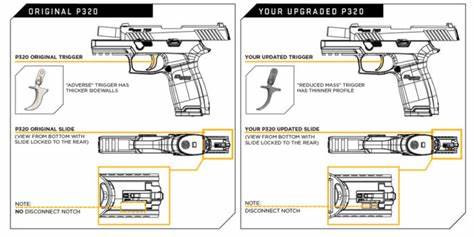

Voluntary Upgrade Program

The drop safety issue only effected one type of curved trigger dropped at a very precise angle. I prefer the feel of the flat trigger.

SIG has decided that two parts are unnecessary, the Safety Spring and Striker Return Spring. SIG has stopped installing them on new guns. If you have them and you like them, keep them.

Grip Modules and Magazine Capacities

The P320 comes in four grip module sizes. The easiest way to understand the names is to think of them in terms of magazine capacity (using a 9mm as standard).

21 round magazine:

A 21 round magazine comes with the M-17, XFIVE and other high end guns. The magazine base extends below the full sized grip module and may not be compatible with older grip modules.

17 round magazine:

The Full Size, Carry, and XCarry grip modules all have a full length grip, and accept a flush fit 17 round magazine. The difference is that the Full Size has a dust cover that goes all the way to the end of the slide on a 4.7″ barreled slide.

The Carry and XCarry grip modules have the same grip length as the Full Size, but they have a shorter dustcover, which will go to the end of a 3.9″ barreled slide, like the “Compact” or “Carry” pistols have.

15 round magazine:

The Compact, and XCompact grip modules both accept a flush fit 15 round magazine. The difference is that the Compact grip goes to the end of a 3.9″ slide, whereas the XCompact grip has a shorter dustcover, which will line up perfectly with the end of a 3.6″ barreled slide, like found on the Subcompact slide.

The P320 XCompact features a redesigned modular polymer XSeries grip with a reduced fastback carry cut and a low-profile internal magwell. Combined with the extended beavertail and high undercut trigger guard, the XCompact offers concealability with improved recoil control.

SIG made this nomenclature confusing, since unlike the Carry and XCarry (both of which have a 3.9″ barrel), the Compact and XCompact have different length barrels (3.9″ and 3.6″ respectively). Another way to think of the XCompact would be as an “XSubCarry”.

12 round magazine:

The Subcompact grip module uses a flush fit 12 round magazine.

Sizing the grip module is not just about how it feels. Check to see if you can effectively reach the trigger. On the gripping hand, can your thumb touch other fingers when gripping? If the grip fits, you are good. 90% of shooters need a medium grip.

P320 Iron Sights

SIG iron sights are common across many different models and calibers. They are numbered for size in such a way that a higher number on front or rear will raise the point of impact. Each number increase on the front sight raises the impact 1 inch at 25 yards. Each number increase on the rear sight raises the impact 2 inches at 25 yards.

Before you adjust a sight, make a pencil mark on the frame next to the sight. This will give you a reference how far you moved. A pencil mark’s width will move the impact of the round approximately 2 inches at 25 yards. SIG make a sight pusher for the P320, other models may not work. Sights install from left to right because there is a taper on the sight base.

Fun Facts and Factory Recommendations

There are 3 integral safeties built into the design:

- Take down lever

- Take down safety lever

- Striker lock

SIG Recommends you keep the following Spare parts:

- Trigger bar spring

- Trigger bar

- Extractor

- Recoil spring

The trigger stop pin used to fall out if the fire control unit was removed from the grip module. Later models staked the trigger stop pin in. There is no difference in function when the gun is assembled.

SIG recommends that you replace the recoil spring at 10, 000 rounds on full size models and 5, 000 for carry compact sub-compact models.

Armorer inspection is recommended by SIG every 3 years or 5, 000 rounds.

If you slam the magazine in to try to allow the slide forward you can damage the ejector. Mags can be over inserted

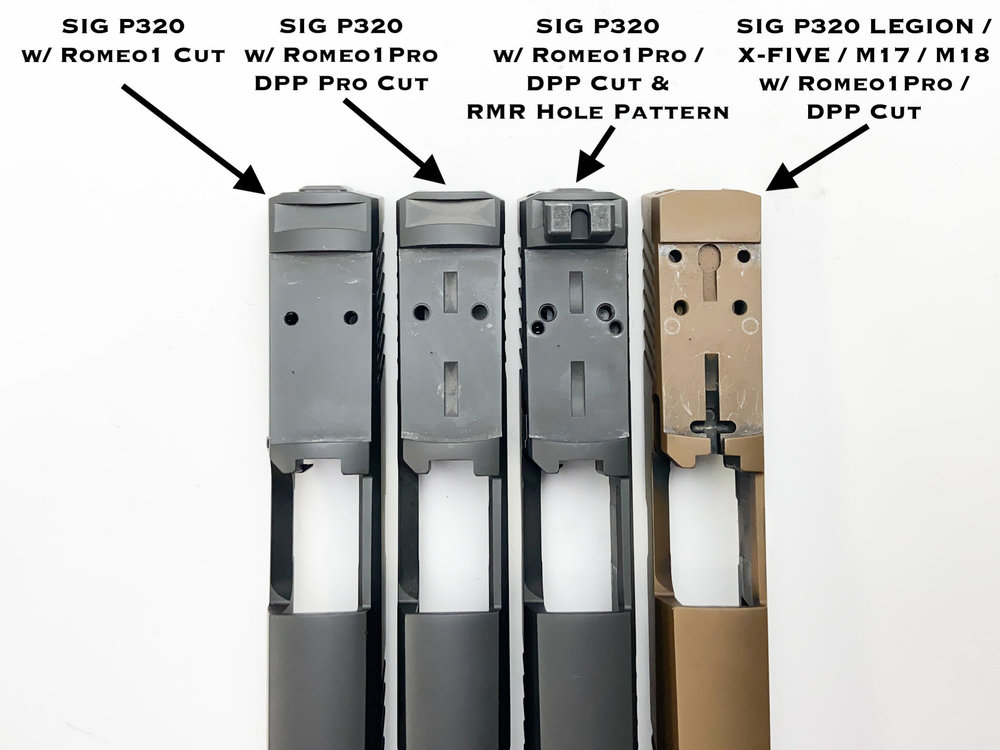

Optics and Footprints

New optic ready P320RXP models have a Delta-Point footprint which is curved at the front. Older P320RX guns have a proprietary footprint which fits the ROMEO1 which is straight across the front.

P320 X-5 models, M-17 and M-18 models (military and civilian) have cover plates which incorporate the rear sight. Each model is a unique challenge for optic mounting.

There are aftermarket slides such as the excellent Grey Ghost Precision Slide which will accept several different optice.

Aftermarket adapter plates can assist in putting the optic you want on the slide you have. The market is constantly changing, you have to do your home-work on this one.

Fire Control Unit: Parts and Up-Grades

All P320s share the same FCU parts. The high end Legion models and the new Custom Shop Fire Control Units have the same parts from the same bins as the lowest priced standard P320 except for the trigger.

The P320 internals are a solid design and aftermarket parts such as the NP3 coated FBMG P320 upgrade kits can offer a real advantage when you are doing a build or just want to improve your performance.

The popularity of the P320 has made parts very hard to come by. Factory (OEM) parts don’t provide the performance that modern gun owners expect. Custom guns like 80% builds let shooters get the exact parts they want, the way they want them.

FBMG USA has P320 FCU parts and slide completion kits in stock. All MIM parts in these kits are NP3 coated for self-lubrication and corrosion/wear resistance. All pins are hardened and coated with Black Oxide for the best corrosion and wear resistance without changing any dimensional tolerances.

The P320 family has the modular flexibility to give you the gun you want the way you want it. If you want to explore and create, there is no better option. Barrel length, caliber, slide cuts, optics or grips, all can be changed in seconds with an ever increasing variety of parts. Why wait?

What handgun did Sig Sauer build the Sig Sauer P320 after; what was their base design for the P320.