Walk into any range day, training course, or SWAT briefing, and you’ll spot it right away: two distinct tribes of plate carrier enthusiasts.

On one side; the old-school MOLLE crew, rocking stitched webbing that looks like it could survive a direct hit from a belt-fed machine gun. On the other, the laser-cut MOLLE crowd, gliding around in streamlined carriers that look like they were designed by NASA.

Both are battle-proven. Both have their loyalists. But in 2025, which one’s the better choice for your loadout? Let’s break it down.

Laser cut webbing is important because it is a modern upgrade to traditional MOLLE that offers some clear performance benefits like weight reduction, low-profile design, increased structural integrity, modern aesthetics, compatibility, and easier manufacturing precision.

A Quick History Lesson on MOLLE

MOLLE (Modular Lightweight Load-Carrying Equipment) hit the scene in the late ’90s as the U.S. military’s answer to bulky, fixed-load gear. The stitched nylon webbing let operators attach pouches, holsters, and tools exactly where they wanted them; mission-specific and highly customizable.

For decades, traditional MOLLE webbing has been the standard for tactical vests, packs, and pouches. And it’s earned that place the hard way, through dust, mud, heat, and freezing cold. If gear could talk, MOLLE webbing would have a thousand stories.

Interested in testing RTS Tactical gear? Police departments can request a FREE T&E today!

Enter Laser-Cut MOLLE

Fast-forward to the age of advanced fabrics and precision-machine cutting. Laser-cut MOLLE ditches the extra stitched-on webbing and instead punches attachment slots directly into a tough, laminated material.

The result?

- Lighter: Fewer layers means less weight.

- Sleeker: No raised webbing to snag on door frames or brush.

- Modern-aesthetic: Let’s be honest, it just looks sharper.

If traditional MOLLE webbing is a Humvee, laser-cut MOLLE is an armored Tesla.

Interested in testing RTS Tactical gear? Police departments can request a FREE T&E today!

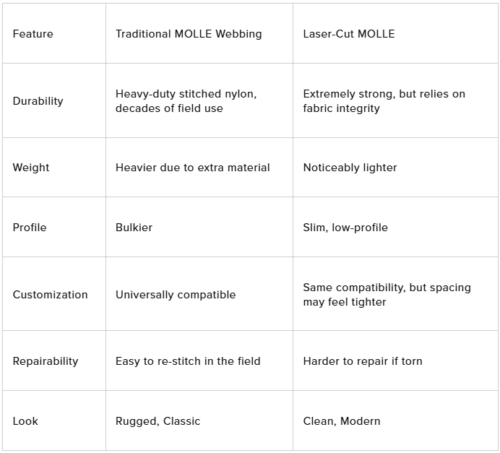

Side-by-Side Showdown

Where You’ll See It at RTS Tactical

At RTS Tactical, we don’t play favorites, we use both systems where they shine.

- Traditional MOLLE: Found on heavy-duty carriers where absolute durability is the priority, like the RTS Tactical Premium Plate Carrier. If you’re stacking a lot of gear and expect hard use, stitched MOLLE webbing takes the beating.

- Laser-Cut MOLLE: Featured on our lighter, fast-response setups like the RTS Tactical OPSEC Plate Carrier, HST Plate Carrier, RICO Vest, Slim Tactical Vest, and Uniform Vest. These are perfect when you want mobility, reduced weight, and a clean profile without sacrificing protection.

So, Which One Should You Choose?

- Pick Traditional MOLLE Webbing if you value maximum toughness, don’t mind extra weight, or want that classic tactical aesthetic.

- Pick Laser-Cut MOLLE if speed, mobility, and modern style are your top priorities.

At the end of the day, both systems will get the job done, it just depends on your mission profile. The good news? Whichever you choose, RTS Tactical has you covered with gear built to last and perform in the field.

Pro Tip: Still can’t decide? Try our Test & Evaluation Program – get hands-on with both styles, run them in your own environment, and see which one feels like home.

Interested in testing RTS Tactical gear? Police departments can request a FREE T&E today!