In the annals of military architecture, the Quonset hut stands as an enduring symbol of resourcefulness and adaptability. These unique prefabricated structures, known for their distinctive curved shape, have played a vital role in military operations around the world. Hundreds of thousands were produced during World War II and military surplus was sold to the public.

The story of Quonset huts dates back to World War II. In the early 1940s, the United States Navy faced a pressing need for quick and cost-effective housing solutions to accommodate the rapidly expanding military forces. To meet this demand, engineers developed a simple, lightweight, and easily transportable structure that could be assembled rapidly in various locations. The George A. Fuller construction company manufactured them, and the first was produced within 60 days of signing the contract.

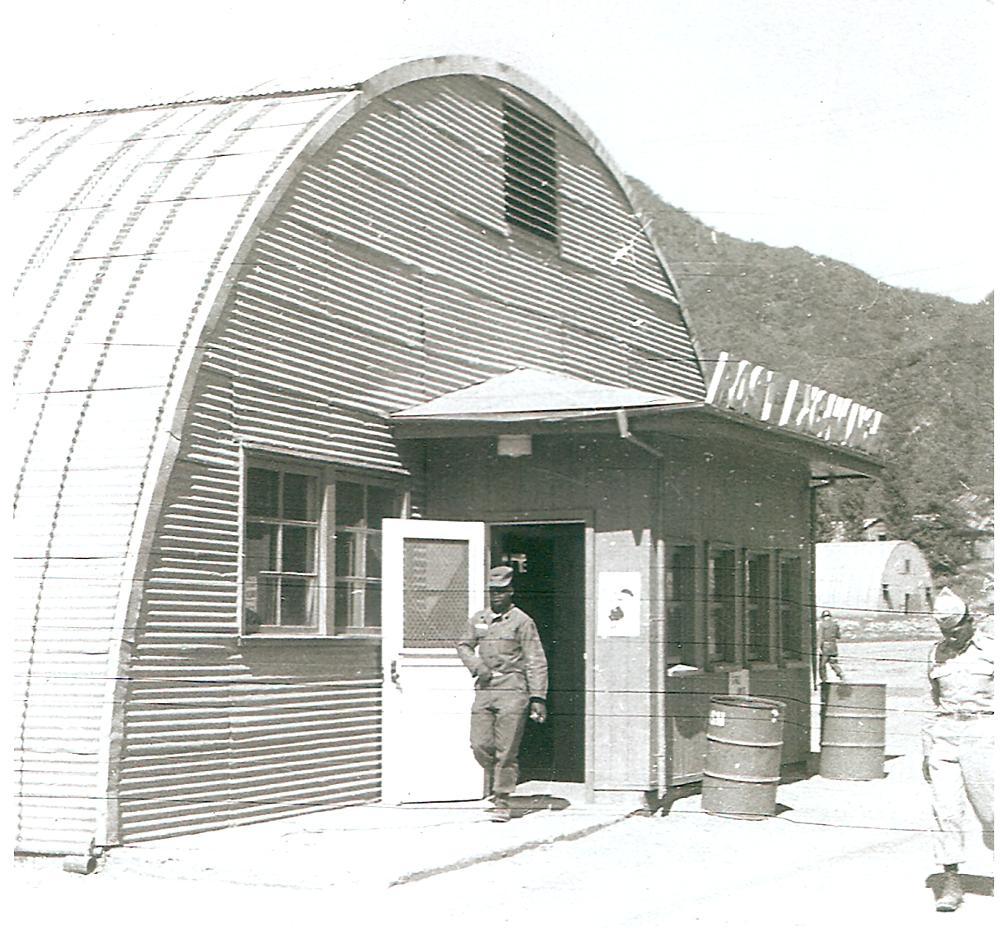

The design of the Quonset hut was inspired by the Nissen hut, a British prefabricated structure utilized during World War I. Named after the town of Quonset Point, Rhode Island, where the first huts were manufactured, the Quonset hut featured a semi-circular shape made from corrugated steel sheets.

Quonset huts’ versatility made them ideal for a wide range of military applications. Initially used as barracks, mess halls, and storage facilities, they soon found diverse uses, including hospitals, offices, recreational spaces, and even chapels. Their modular design and ease of assembly allowed for rapid deployment and relocation, making them invaluable in various military campaigns, from the Pacific Theater to Europe.

The sides were corrugated steel sheets, and the two ends were covered with plywood which had doors and windows. The interior was insulated and had pressed wood lining and a wood floor. The building could be placed on concrete, on pilings, or directly on the ground with a wood floor. The original design used low-grade steel, which was later replaced by a more rust-resistant version. The flexible interior space was open, allowing use as barracks, latrines, medical and dental offices, isolation wards, housing, and bakeries.

Following World War II, surplus Quonset huts found new life in civilian sectors. The portable and affordable nature of these structures made them popular for commercial and residential purposes, particularly in remote areas or during times of housing shortages. Many Quonset huts were repurposed as warehouses, workshops, agricultural buildings, and even homes, leaving a lasting architectural legacy.

The original Quonset huts were made of corrugated steel, providing durability and weather resistance. Over time, advancements in construction materials and techniques have led to the development of modified Quonset huts with improved insulation, energy efficiency, and structural strength. Modern variations incorporate materials like aluminum, fiberglass, and even fabric covers, offering enhanced performance while retaining the iconic curved shape. Between 150,000 and 170,000 Quonset huts were manufactured during World War II, and the military sold its surplus huts to the public after the war. Some are still in active use at United States military bases. The U.S. Department of Energy continues to utilize Quonset huts as supporting structures (fabrication and machine shops, warehouses, etc.) at the Nevada National Security Site.