There are so many different cleaners and lubricants available on the market today. You have a wide variety of choices out there from toxic chemicals to green products that are even food-grade. Breakthrough clean is designed to be an Eco-Friendly product that can offer superior lubricity and cleaning ability demanded by all shooters. The kit that I used for this test was something that came in a Gunner Crate shipment that my wife got me for Christmas.

The Breakthrough kit came with a 2oz bottle of their Military Grade Solvent, 2oz of Battle Born High-Purity Oil, 2 small packets of grease, a green microfiber cloth, and a standard weapons cleaning brush. The whole kit usually goes for about $25 on Amazon. Not a bad price when you consider all that you get and the cost that each item may cost if purchased separately.

MILITARY USAGE?

TESTING STANDARDS

My goal during testing was to perform a couple of tests to see what the capabilities of the product are. First I tested the solvent independently, and followed it up by testing the lubricant and solvent together. My standard go to products for cleaning and lubrication is SLIP2000 products. Their CLP has outperformed all other CLPs on the market that I have tested, and the cleaning has always been expedient from the first time I have used it. Basically, SLIP2000 is my baseline in how I judge and define a quality lubricant.

A quality lubricant, to me, should be able to prevent fouling from being able to stick to any surface so that it can be simply wiped away with a cloth or by the action while firing the weapon. That being said, the most challenging area on a pistol to keep clean is the bore, and the crown of the barrel. A quality lubricant should perform well and keep the action wet, despite being bombarded by carbon fouling. Many lubricants, in my experience, have problems with staying on the metal and performing under the pressures presented by using a firearm.

MILITARY GRADE SOLVENT

The Breakthrough Military-Grade Solvent is made of distilled petroleum products and is completely clear, as is the case for the other Breakthrough products. It is designed to have the same characteristics as the other Breakthrough products in terms of being non-toxic, non-carcinogenic, odorless and so on. It is said to be capable or removing all firing residue, copper fouling, plastic wadding, and lead. Yet this product is claimed to be safe to use on all metal, polymer, wood, Hydro-printed and Cerakote surfaces. After talking to a representative at Breakthrough, I learned that the solvent is best used in conjunction with THEIR oil and grease in order to get the best results.

DRY TEST

The first test I performed for the solvent was to shoot the Beretta PX4 Storm 9mm for 300 rounds in a bone dry state. Now, when I fired the PX4 in this completely bone dry state, the pistol suffered noticeable amounts of wear on the barrel, inside of the slide where the barrel rubs, and the locking block. This would clearly indicate that the pistol will show the effectiveness of a lubricant by how well it prevents this aggressive wear.

When I began the cleaning process for the pistol, I wanted to start with a wipe down just to see where the carbon fouling stuck to the firearm in order to know where the solvent could be best tested. During this wipe down and running a dry bore snake through the barrel, I noticed that the breechface, the feed ramp, the crown, and the bore were the only areas that had stubborn carbon fouling buildup. Since the PX4 is outfitted with a chrome-lined barrel, I figured that the solvent would have a relatively easy time cleaning out the remaining carbon fouling. Therefore, following the instructions for the solvent, I sprayed the effected areas where the fouling built up the worst and let it sit. The solvent, being very thin, covered the affected areas very well after just one light spray to each area. In fact, one spray darn near made the solvent pool up to the point of almost running and dripping. Basically, a little bit of the solvent goes a very long way.

[amazon_link asins=’B00U41UXVQ’ template=’ProductCarousel’ store=’spoup-20′ marketplace=’US’ link_id=’7411450c-f72c-11e7-8545-8583a883cf2e’]

After allowing the solvent to work on the carbon buildup for about a minute or two, I used the provided microfiber cloth to wipe down all the caked on areas, save for the bore. With a simple wipe, the feed ramp was completely clean. With a little elbow grease applied to the feed ramp, all brass markings and carbon came right off. Now it was time to test the bore. I simply used the same bore snake I used for the wipe down test. After running the bore snake through one time, I saw that there was very little difference in the buildup. A tiny bit may have been taken away by the solvent, but it clearly failed to penetrate the fouling too well. Basically I was not too impressed with the dry results of the test, but then again, it was not designed to be so aggressive on stubborn fouling. Instead, it was designed to use the stubborn characteristics of the oil to assist in cleaning. Basically, the oil is designed to hold back the fouling from caking into the metal so the solvent can get between the fouling and the lubricant and allow the fouling to be swiped away with ease. At least that is the theory of how this system is supposed to work.

BATTLE BORN OIL

The Battle Born Oil that Breakthrough has developed is claimed to be made of 100% highly refined synthetic oils. As is the standard for the other Breakthrough products, it too is non-carcinogenic, odorless, etc. You will notice that the bottle says that the oil has an operating temperature of -90 to +417 degrees Fahrenheit. To me, this is a kind of low operating temperature. This is something I would say might be a better performer strictly in extremely cold environments like in Northern Alaska where just the ambient temperature will keep your weapons running cool for the most part.

The Battle Born oil is designed to be a lubricant and protectant only, which most people would consider a much better system for lubricating your firearm. The theory is that this helps the product focus on doing one thing well instead of doing everything somewhat well. I have personally never noticed that a product like this actually LUBRICATES so much better than a CLP. I think that this even raises the question of how people are testing these theories.

THE TEST

The clear oil seemed to give the metal surfaces a nice and smooth look and feel. I will also note that this oil does cover a large surface without needing that much, which could be a good thing. The real test for this lubricant is how well it prevents carbon fouling from sticking to metal surfaces in the bore, on the breech face, and the feed ramp. For the testing I conducted, I lubricated the bore, barrel, locking lug, breech face, feed ramp, slide, and the guide rail channels. As the instructions recommended, I let the lubricant sit for a while before shooting in order to allow it to get a better bond to the metal surfaces.

During my testing of this oil, I fired 200 rounds as fast as I could load and fire them. The gun did get hot enough to where I could easily feel the heat through my thick Kydex holster. After disassembling the pistol, I found that the oil was still on the barrel and there was no noticeable wear, which was unexpected for me. The locking lug was still very wet and the lubricant did not seem to show any evidence of thinning out. I noticed that the feed ramp and the breech face had a light coating of carbon fouling. I used a paper towel to wipe both areas and noticed that it took little to no effort to clean off these areas. In fact, I noticed that the metal still had a slick surface as if the lubricant was still there. That was really impressive, since I figured that this thin lubricant would get overwhelmed just at this round count.

After wiping down the rest of the pistol with a simple paper towel, I ran a dry bore snake through the barrel. After one pass, I noticed that the barrel had little fouling in the grooves of the rifling. The last third of the bore on the muzzle end had the worst buildup of fouling, which I have found is normal. For a lubricant only rated for 450 degrees, I was pretty impressed with the performance.

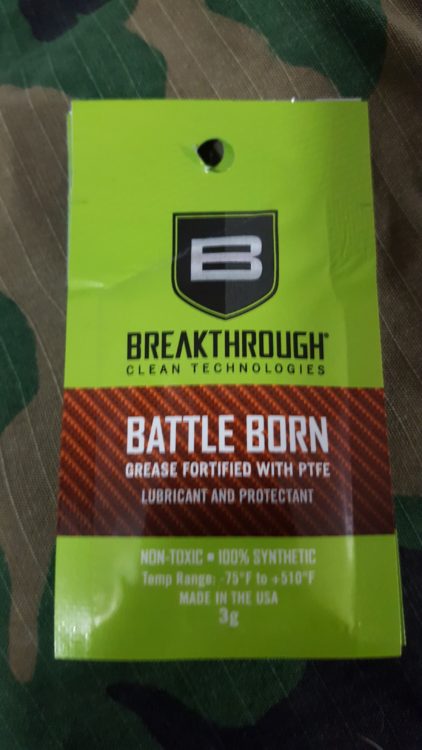

BATTLE BORN GREASE

It seems that almost all gun lubricant companies have come out with their own grease. Breakthrough Clean has their own grease that is basically their Battle Born oil with added thickeners and PTFE to enhance lubrication. The grease is claimed to be operational from -75 to +510 degrees Fahrenheit. This temperature range may seem somewhat low, but I think I understand why. The PTFE(Teflon) in the grease has a max operational temperature of 500 degrees before it starts breaking down and burning off. When PTFE burns off, the vapors are incredibly toxic and dangerous if inhaled.

The grease has the texture of Vaseline, is clear, and has the faint odor similar to that of those Elmer’s glue sticks that I used in school. I did not see a point in testing the grease because I figured that it would mostly only see use in areas that are well away from sources of extreme heat such as the rail channels. The general role of grease is to enhance the lubrication of areas that may need a thicker lubricant, like on the rails of the Sig P226/229 style pistols. Grease also seems to be very stubborn compared to oil and alot harder to overwhelm with carbon fouling.

SUMMARY

As a kit, it would seem that the Breakthrough products are generally effective at lubricating and cleaning. I would not say that the solvent is too incredibly effective all on its’ own. As it was apparent in my testing, the solvent needs the help of the oil in order to clean more effectively. I am not so sure that I would classify it as an aggressive and impressive cleaning agent, given the results of my testing.

The oil did impress me with its performance. It held off the carbon fouling in the high pressure areas relatively well, even for just having been put on a few hours before shooting. The oil did not seem to splatter everywhere when shooting, despite being incredibly thin. The oil did not keep the fouling wet and float it away like many CLPs do, but it did prevent the buildup from really sticking.

Overall, I would say that the kit seems to work relatively well in applications where you fire a few hundred rounds at a time. I would have to test the product further in order to see how effective it is at keeping an AR bolt wet and clean. So far, I think this product will serve the majority of pistol shooters just fine.

*The views and opinions expressed on this website are solely those of the original authors and contributors. These views and opinions do not necessarily represent those of Spotter Up Magazine, the administrative staff, and/or any/all contributors to this site.

Brought to you by the dudes at Spotter Up

Good day sales. My name is Dean Dominic i want to purchase some of your products to Nauru. Can i e-mail my order needed then you can give me a quote here and make charges to my credit card Manually, I have a private freight company who will handle the pick up. -Can you ship to Nauru? -Do you accept credit card? -Do you have QuickBooks to send electronic online payment? -What is the delivery time? Pls Clarify. Looking forward to your swift response then we can proceed further as soon as possible

Thanks

Dean Dominic (CEO)

5625500947