Silence is golden. When it comes to firearms, quieter is definitely better. Hollywood is largely responsible for the negative (and erroneous) views many Americans hold regarding “silencers.” There are numerous benefits to suppressors in addition to their tactical applications.

Laws regarding suppressors vary around the world. Although here in the US suppressors are tightly regulated, many countries don’t view firearms sound suppressors as nefarious devices only suitable for assassins. Shooting quieter and not disturbing one’s neighbors is simply the polite thing to do. They’re also considered an important form of hearing protection for shooters, and rightly so. In some countries, such as Finland, France and New Zealand for example, they’re completely unregulated.

And fortunately, here in the US attitudes and laws are changing for the better as more people recognize the benefits of suppressors. According to the American Suppressor Association, as of this writing law-abiding citizens in 42 states can own suppressors and hunters in 40 states are now allowed to use suppressors to help protect their hearing in the field.

There have never been more options than there are today when it comes to firearm sound suppressors. So how does one go about selecting the right suppressor for the job? Let’s start with the basics.

The Nature of Sound

Sound is the sensation that’s experienced when the brain interprets vibration within the structure of the ear caused by rapid variations in the air pressure. Sound is commonly measured in decibels (dB). They’re logarithmic in nature. What this means is that for every dB the intensity will increase by a factor of 10

The specification of the intensity of the sound, as ordinarily used, implies a comparison with the smallest level of sound detectable by the human ear. The smallest level of sound that can be detected by the human ear is around one dB (0.1 bel). Normal conversation is around 60 dB. The average threshold of pain for the human ear is around 130 dB.

According to the US Occupational Safety and Health Administration (OSHA), the threshold for a hearing safe impulse noise is 140 dB. Without hearing protection, exposure to any impulse noise over 140 dB causes varying degrees of permanent noise-induced hearing loss. It can also lead to tinnitus. Most well-engineered suppressors take the dB level of their host firearm below 140 dB, making those suppressors effective primary-hearing safety devices.

There are two types of noise that can damage hearing: 1) short-duration, high-intensity noise, such as gunshots, and 2) prolonged exposure to lower levels of noise. Although individual sensitivity varies, many authorities believe that prolonged exposure to noise above 85 dB can lead to hearing damage. Hearing damage is cumulative and irreversible.

Silencer or Suppressor?

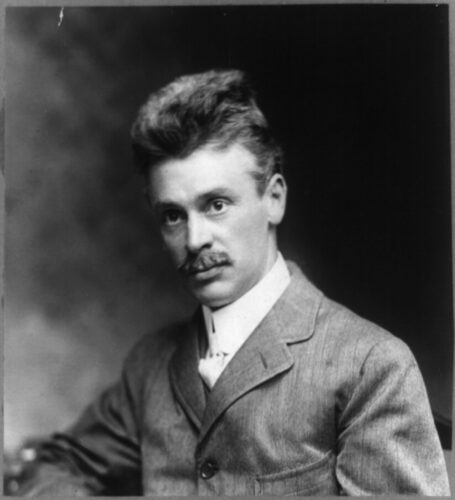

Silencer or suppressor, which is correct? Rather than quibble about it, let’s go to the origins. Hiram Percy Maxim, the son of Sir Hiram Maxim (inventor of the Maxim Machine gun), is generally credited with inventing the first commercially successful firearm sound suppressor around 1902. It received a US patent on March 30,1908. Maxim called his device the Maxim Silencer. If the term “silencer” was good enough for Maxim, it’s certainly good enough for me. And it should be good enough for you, as well.

Sound suppressors have come a long way since the Maxim Silencer, but the basic principles of their operation are the same.

How Firearm Sound Suppressors Work

There are three possible sources of sound from the discharge of a firearm that need to be considered when silencing a firearm: the weapon’s report, i.e., muzzle blast; the “crack” caused by a supersonic bullet passing the sound barrier; and the sound from the cycling of the firearm’s action.

The muzzle blast is the most significant source of sound that’s generated by a firearm. Muzzle blast is the consequence of the shock waves resulting from high-pressure gases exiting the barrel. If the pressure is reduced immediately before it exits, the weapon’s report will be reduced.

The Combined Gas Law or General Gas Equation states the relationship between pressure, volume and temperature. Pressure is inversely proportional to volume (higher volume equals lower pressure). Pressure is directly proportional to temperature (higher temperature equals higher pressure).

Muzzle blast is also reduced by decreasing velocity of the gases and either absorbing the sound waves or canceling them by interference with reflected waves coming from the same source.

Sound waves behave in many ways similar to light waves. As with light waves, sound waves can be reflected, refracted, diffracted and scattered. Various combinations of components, such as baffles, spacers, packing material, mesh, expansion chambers, spiral diffusers, pressure relief ports, and wipes may be employed in a suppressor to “silence” a firearm.

As a suppressor accumulates fouling during firing, its effectiveness will deteriorate. The maintenance requirements will differ depending on the suppressor. Some baffled systems are designed to be self-cleaning or require nothing more than dunking in solvent to clean out the fouling. Other designs may require repacking or the replacement of wipes at the factory. It should be noted that in silencer parts fall under provisions of the National Firearms Act (NFA).

Weapons with ported barrels and integral sound suppressors do not require the use of subsonic ammunition for effective sound reduction. They’re designed for specialized applications that require fully realized sound and flash suppression. Because the suppressor is integral to the weapon, the weapon may not be used in a non-suppressed mode.

Muzzle sound suppressors are more versatile than integral suppressors, in that they can easily be removed when sound suppression is not necessary. If subsonic ammunition is employed, muzzle suppressors are often every bit as quiet as an integral suppressor. Because they do not reduce the velocity of a bullet, higher terminal velocities are possible for applications in which a sonic crack isn’t an important tactical consideration.

Selecting a Sound Suppressor

When selecting a sound suppressor/weapon system, a variety of factors need to be taken into consideration. These include the operational requirements in the mission in which it will be employed, any special ammunition requirements, cost, maintenance and any required modification to the weapon. Other considerations include point-of-impact (POI) shift between suppressed and unsuppressed, construction, back-pressure and thread-on vs. quick attachment system.

Any comparisons between suppressors need to be carefully considered, since the method of testing that’s utilized by manufacturers may vary from manufacturer to manufacturer, making comparisons difficult, unless one has the details as to how the testing was conducted. US military requirements for testing are specified in MIL-STD-1474C.

When you put on or take off a suppressor, you will typically see some POI shift. There are two types POI shift when mounting a suppressor and POI shift from shot to shot. POI shift when mounting a suppressor is more impacted by the threads on the weapon than the suppressor. POI shift isn’t as much of an issue if it’s repeatable as the shooter can easily correct for the shift. POI shift from shot to shot is most often related to the mounting system of a quick attach suppressor.

Threading on a suppressor is the strongest, most precise method of mounting a suppressor. They are generally more accurate and less prone to alignment issues and baffle strikes, although thread mount suppressors can work themselves loose and out of alignment. Thread mount suppressors are widely used on precision rifles.

A quick attach suppressor does have advantages over a threaded suppressor for certain applications. Quick attach suppressors allow the end user to more easily switch the suppressor between different weapon platforms, although they generally require the use of proprietary mounts.

A variety of materials may be employed in the construction of a suppressor. Each has its pros and cons. Suppressor baffles are under extreme stress and the materials that are utilized must be matched to the application. Stainless steel is a common material utilized in suppressor applications. It’s durable, corrosion resistant, and handles heat well. It’s also relatively low cost. A disadvantage is weight.

Titanium is lightweight and durable. It’s often used where light weight and precision are important, such as in 7.62mm and larger bore applications. The downside to titanium is that it cannot handle the heat generated by high volumes of fire.

Suppressors utilizing high-temperature alloys such as INCONEL® are designed to withstand the high heat generated when employed in a high-volume fire role. Suppressors with INCONEL baffles may cost a little more, but they make up for the initial cost in the long term with extended service life.

INCONEL is the trade name for a family of austenitic nickel-chromium-based super alloys made by Special Metals Corporation that are designed for extreme environments. INCONEL offers a combination of heat resistance, high-temperature corrosion resistance, toughness and strength that makes it ideal for suppressor blast baffles.

Back-pressure from the suppressor also needs to be considered. Suppressing a weapon can significantly increase back-pressure. Excessive backpack pressure will increase the cyclic rate, causing weapon malfunctions, reduce the service life of the weapon, spit gasses back into the face of the operator, and cause increased fouling. The back-pressure created by traditional suppressors can be eliminated to a great degree by suppressors designed to control the gasses rather than simply trap them. Up to a 95-percent reduction is claimed.

Suppressors with improved gas flow dynamics can also largely eliminate the first round pop (FRP) and flash common with traditional designs. With traditional suppressors, the first round is often louder than subsequent rounds and there may be a slight flash. This is the result of the oxygen in the suppressor burning off, which makes the first shot louder than subsequent shots. Use of an artificial environment will also largely eliminate first round pop/flash.

A sound suppressor can substantially reduce the recoil velocity and recoil energy of a firearm. Gas volume and gas pressure at the muzzle are major factors in the free recoil energy produced by a firearm. All other factors being equal, increased gas volumes and higher gas pressures at the muzzle will increase the recoil velocity and free recoil energy. Sound suppressors reduce the free recoil energy by suppressing the effects of the expanding powder gasses. They also add weight, slowing the acceleration of the weapon.

The suppressor also greatly reduces any ground disturbance when firing from a prone position. Many shooters find that their accuracy improves when a suppressor is employed, due to the resulting reduction in the muzzle blast and recoil. The reduction in recoil also permits quicker follow-up shots.

When selecting a suppressor, size may be an important consideration for some applications. Size and performance are generally inversely related. Although suppressor design (and choice of ammunition) can help overcome some of the performance deficits with smaller suppressors, you can’t change physics.

While sound suppressors may still have an image problem in the eyes of many people, they are valuable tools whose benefits go beyond the tactical. However, there are a number of factors that need to be considered when making purchasing decisions.

Sources

American Suppressor Association

www.americansuppressorassociation.com

SIG SAUER

www.sigsauer.com

*The views and opinions expressed on this website are solely those of the original authors and contributors.These views and opinions do not necessarily represent those of Spotter Up Magazine, the administrative staff, and/or any/all contributors to this site.

What is meant by “use of an artificial environment” to reduce first round pop? Do you flood the can with CO2 or something?

An artificial environment or “wet” suppressor utilizes an abative medium such as water or other wet medium inside the suppressor system to cool the gasses much faster by transferring the heat energy into the liquid (or gel) medium causing a rapid drop in pressure for additional sound reduction. The internals are very similar or identical to the wipeless suppressors.