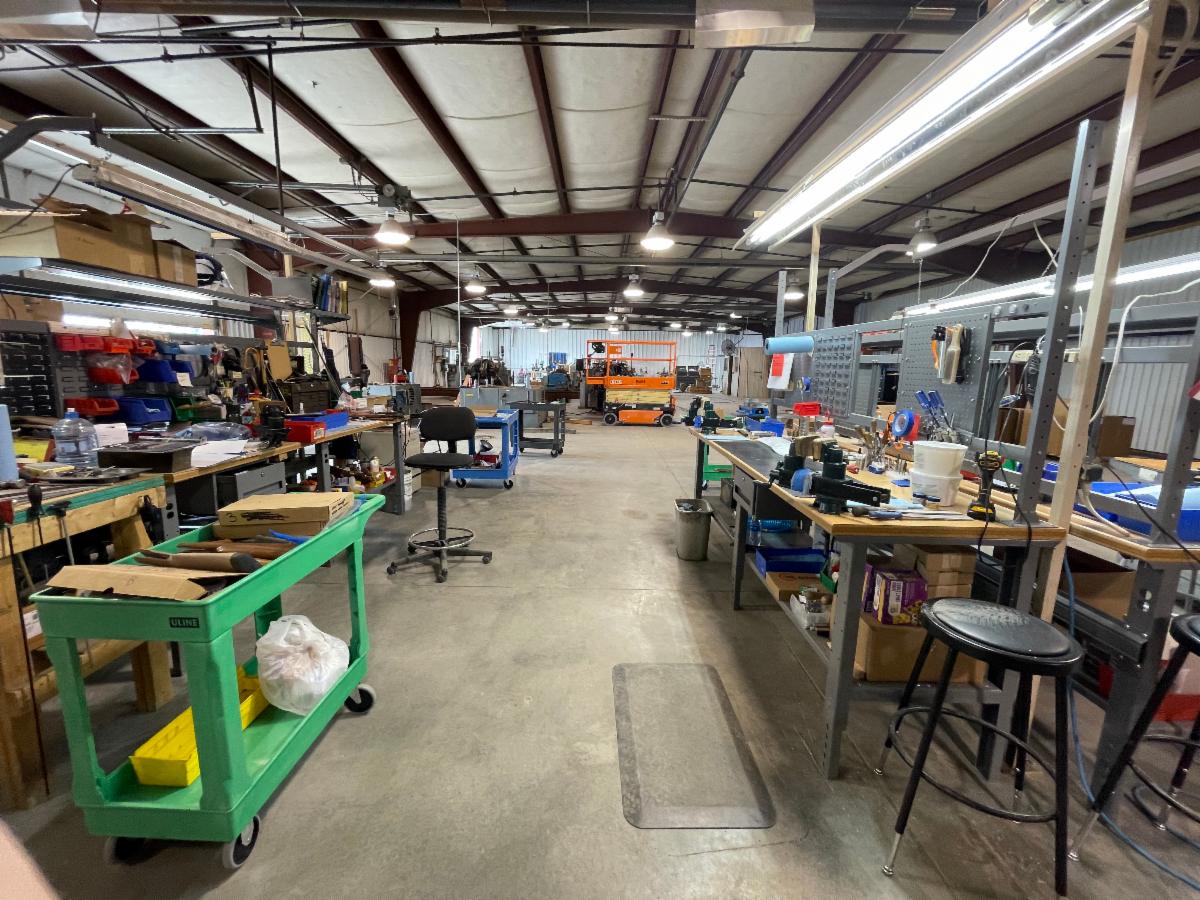

The new facility offers the power and space for BHA to operate additional machinery, as well as increase inventory storage space.

Cody, Wyo. (May 2022) – Big Horn Armory (BHA), makers of big-bore firearms, has completed the relocation of its offices and manufacturing facilities to 319 N. Blackburn St., Cody, Wyoming, 82414. The new facility is over five times the size of the previous location, providing more manufacturing space to operate additional machines and better facilities for building BHA’s firearms. It also provides increased space for maintaining a larger inventory. These factors combine to make BHA’s operations run much more smoothly and efficiently than at the old facility and will aid in improving lead times in the next few months.

“The move to our new, larger facility offers expansion space for additional equipment and employees,” commented Greg Buchel, Owner of Big Horn Armory. “It will allow us to increase our manufacturing capabilities many times over what we could formerly accomplish. We look forward to supporting our local economy in Cody, Wyoming by creating many good, stable jobs within our company.”

BHA has increased its workforce in the manufacturing department by 20 percent since October 2021 and intends to double its staff by year-end. Nine new machines are anticipated to be on the manufacturing floor by the end of May 2022. All of the new equipment has CNC capacity with a mix of mills and lathes and barrel-making equipment, which will help to lessen the dependency upon outside vendors. BHA has consistently been adding vendors over the past year and intends to add more. With a larger pool of sourcing suppliers, supply chain issues will be minimized and will help to reduce lead times on customer orders.

“We believe in building American-made, heirloom-quality firearms with attention to detail offered in unique, big-bore calibers and as such have invested in our manufacturing capabilities to match up with our beliefs,” Buchel stated. “We appreciate our customers’ patience during this relocation process. As we finish settling in to the new facility, we continue to fulfill our orders and implement improvements to meet our customers’ needs. We anticipate reducing our lead times by half or better once we are 100 percent up and running.”