Eye pro isn’t just for the range or battlefield. Eye injuries can happen virtually anytime and anyplace. And those designer sunglasses that you may be wearing likely don’t provide the level of protection that you need.

According to the Centers for Disease Control and Prevention (CDC), approximately 2,000 eye injuries occur every day at work in the US. Wearing the proper eyewear could prevent more than 90% of all eye injuries. So what constitutes proper eyewear? And what should one look for when selecting it?

Protective eyewear can be divided into two basic types — glasses (spectacles) and goggles. In this article we will take a look at protective glasses. The article might be a bit technical at times, but it’s necessary for a thorough understanding and to help you make the best choices.

Protection

Non-prescription sunglasses sold in the US are regulated by the Food and Drug Administration (FDA) as Class 1 medical devices. They’re required to conform to basic safety standards. Compliance with the voluntary American National Standards Institute (ANSI) Z80.3 standard is considered acceptable.

ANSI Z80.3 establishes establishes standard guidelines for “noncorrective (essentially plano power) lenses that are intended for attenuation of light and for fashion eyewear,” commonly known as sunglasses. ANSI Z80.3 includes standards for impact resistance, flammability, bio-compatibility, and optical properties. The current ANSI Z80.3 Standard is ANSI Z80.3-2018.

The American National Standards Institute is a US non-profit organization that creates uniform testing standards. All ANSI standards are voluntary, but ANSI standards are often adopted by agencies with enforcement authority.

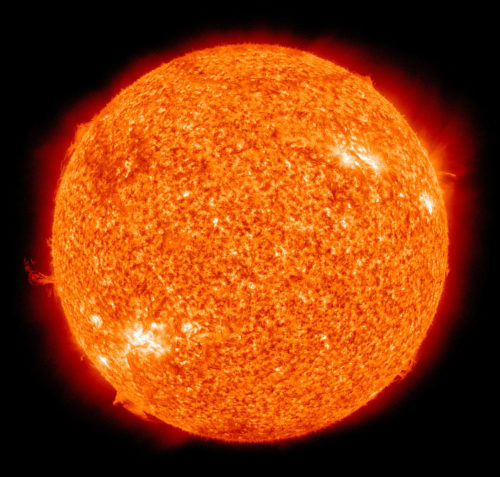

Ultraviolet (UV) protection is covered by the ANSI Z80.3 standard, which also includes elements such as light transmittance, including being able to distinguish between green and yellow light in average daylight.

UV is invisible to the human eye. Long-term exposure to UV has been linked to serious eye damage. The three types of UV radiation are UVA, UVB, and UVC. UVA is the most damaging to the eyes, although UVB has also been linked to eye damage. Most UVC is filtered out by the ozone layer.

High-energy visible (HEV) radiation or blue light can also damage eyes. Although HEV rays have longer wavelengths and lower energy than UV rays, they penetrate deeply into the eye and can cause retinal damage. While some sunglasses block HEV, the FDA doesn’t require it.

We not only need to protect our eyes from the sun but from unexpected eye hazards as well. FDA safety standards for sunglasses don’t provide the level of impact protection that’s essential for active sports, shooting or duty/tactical applications.

Most lenses shatter into fragments when hit by objects moving at easily reached speeds, according to ophthalmologist Dr. Paul F. Vinger, an Associate Clinical Professor at Tufts Medical School in Medford, Massachusetts. Dr. Vinger conducted 350 impact tests on various types of glasses.

In the study, which was published in the January 8, 1997 issue of the Journal of the American Medical Association (JAMA), tennis balls propelled at 40 mph (64 kph) shattered high-index plastic lenses, while balls at 55 mph (89 kph) shattered allyl resin (also known as hard resin or CR-39) plastic lenses and those at 89 mph (143 kph) shattered glass lenses. Polycarbonate lenses didn’t shatter at 89 mph (143 kph). All of the glass and plastic lenses met the FDA standards.

Polycarbonate lenses with a center thickness of one millimeter withstood the impact of a baseball fired at 94 mph (151 kph). An average 10-year-old child can throw a baseball about 50 mph (80.47 kph). Lenses made from glass, allyl resin plastic and high-index plastic shattered at that speed. To quote Dr. Vinger, “Polycarbonate lenses demonstrated resistance to impact for all tested projectiles exceeding the impact potential expected during routine use.”

Developed commercially in 1957, polycarbonates are extremely tough, impact-resistant thermoplastics that have many applications. They’re available in different grades and proprietary blends. Polycarbonates are known by a variety of trademarked names, including Lexan®, Makrolon®, Zelux®, Plutonite®, and others.

Polycarbonate lenses are the most impact-resistant lenses available. They’re lighter and thinner than glass or plastic lenses and have from 10 to 20 times more impact resistance. Polycarbonate lenses have excellent optical clarity, although they can’t match glass lenses in this regard. Polycarbonate inherently blocks nearly 100% of UV and HEV up to 400nm (UV400 protection). It does scratch fairly easily and requires a scratch-resistant coating for durability.

Trivex® is a rival to polycarbonate that was developed in 2001. Trivex lenses and polycarbonate lenses are comparable in impact resistance, inherent UV protection, and scratching. Trivex is approximately 10% lighter than polycarbonate and may have a very slight edge in optical clarity but it’s more expensive.

The ANSI Z87.1 Standard

The ANSI Z87.1 Standard is designed to help eliminate eye and face hazards in occupational and educational settings. The standard provides criteria and requirements for selection, use, and maintenance of the different face and eye protectors to promote the most effective materials and methods of use. Compliance with this standard is also voluntary.

The current ANSI Z87.1 Standard is ANSI/ISEA Z87.1-2020. ISEA (International Safety Equipment Association) is an ANSI accredited standards developing organization for personal protective equipment (PPE) and technologies.

The 2020 edition of ANSI/ISEA Z87.1 is the second revision to be released since 2010. The 2010 revision was important due to a shift towards being more hazards based. Protective eyewear was previously classified as either basic or high impact. Starting with ANSI Z87.1-2010, the distinction now is that they’re either non-impact or impact rated.

In addition to refining these changes, the current version also addresses issues related to the emergence of new technologies that were not previously covered in ANSI/ISEA Z87.1.

ANSI/ISEA Z87.1-2020 doesn’t include certain hazardous exposures such as bloodborne pathogens, X-rays, high-energy particulate radiation, microwaves, radio-frequency radiation, lasers, masers, and sports and recreation.

There are two main tests for Z87+. In the ANSI high mass test, a 500-gram (17.6oz.) pointed weight is dropped from a height of 50 inches (127 cm) onto lenses that are mounted on a head form. No pieces from the frames or lenses may break free or fracture. In the high velocity test, a 0.25-inch (0.635 cm) steel ball is shot at the lens on the head form at 150 fps (45.72 m/s). The pass/fail for the high velocity test is the same as for the high mass test, with the added requirement that no part of the lens may touch the “eye” on the head form

The standard also guarantees optical precision, impact resistance on frames equipped with prescription and standard glasses (made of two-millimeter-thick polycarbonate), anti-fog and anti-scratch coating, UVA and UVB filtering, frame resistance, and side protection.

Impact rated eyewear carry the Z87+ mark on both the lens and the frame or housing. Compliant prescription products are marked with Z87-2+. Commercial eyewear products, even if marked ANSI Z87.1 compliant, don’t necessarily meet military impact requirements.

US Military Combat Eye Protection System Specifications

The US military Combat Eye Protection (MCEP) System specifications for combat eye protection (MIL-PRF-32432A) is even more stringent. MIL-PRF-32432A is a revision (dated 11 September 2018) of MIL-PRF-32432 (dated 9 January 2013) and supersedes it.

MCEP provides protection from dust, flying debris, and ballistic hazards both in training and on the battlefield while maintaining compatibility with existing Soldier equipment. This specification is approved for use by all Departments and Agencies of the Department of Defense.

The MIL-PRF-32432A ballistic fragmentation performance requirement requires Class 1 eyewear (spectacles) withstand two hits with a 0.15-caliber (3.81 mm), 585 (± 0.15) grain, T37 shaped projectile at 700 to 725 fps (213.36 to 220.98 m/s) to the primary lens. This is over seven times the kinetic energy level of ANSI Z87.1 impact tests.

Eyewear meeting military ballistic standards may be identified by reading the manufacturer’s product description or by purchasing those on the US Army’s Authorized Protective Eyewear List (APEL®) Qualified Products List (QPL). APEL qualified eyewear will be labeled on the packaging and frame with “APEL”. Army regulations state that eyewear that’s not on the APEL isn’t authorized for wear during combat, training, or when there’s a risk of impact injury to the eyes. The only exception is where laser protection is necessary.

Laser Protection

Laser protection is a growing consideration, not just for the military but for law enforcement and pilots, as well. For example, most people don’t realize the damage that the cheap, widely sold Chinese-made green lasers can actually do to the eyes. They’re no joke.

Laser protective eyewear is specified by the wavelengths it block (usually given in a range of wavelengths) and the Optical Density (OD), or the strength at which it blocks those wavelengths. Laser protective eyewear is available for every type of dangerous laser. Laser protective lenses may be clear or colored.

The Program Executive Office (PEO) Soldier, which oversees the APEL, states that Special Purpose Eyewear Cylindrical System (SPECS), Ballistic Laser Protective Spectacles (BLPS), Sun Wind Dust Goggle (SWDG), or replacement products specifically approved for laser protection by Project Manager Soldier Protective Equipment (PM SPE) should continue to be used where laser protection is required,

Visible Light Transmission & Other Important Features

Visible Light Transmission (VLT) is the amount of visible (non-UV) light that passes through your lenses and reaches your eye. VLT is measured in percentages. For example, a lens with a VLT of 20% admits 20% of visible light and filters out the remaining 80%. Here are some general guidelines for VLT:

10–19%: Ideal for bright, sunny conditions.

20–40%: Good for all-purpose use.

40+%: Best for overcast and low-light conditions.

80–90+%: Virtually clear lenses for very dim and night conditions.

Lens colors affect how much visible light reaches your eyes, how well you see other colors, and how well you see contrasts. Dark colors (gray, green, brown) excel in moderate to bright light conditions. The darker shades are intended to cut through glare and reduce eye strain.

Light colors (yellow, gold, amber, rose, vermilion) excel in moderate to low level light conditions. They provide excellent depth perception, improve contrast, make your surroundings appear brighter, cut through glare, and reduce eye strain in moderate to low level light conditions.

Grey and green lenses won’t distort colors. However, only grey and clear lenses provide true color perception.

Only eyewear with neutral grey and clear lenses are approved for wear by the military, with the exception of products with approved laser protective lenses. Non-laser commercial lens tints, such as yellow, aren’t approved for use due to their impact on color perception.

Gradient lenses go from a darker shade at the top to a lighter one at the bottom. They’re good for driving as they shield your eyes from overrhead sunlight, while the lower half allows more light to see the dashboard. They’re good for pilots for the same reason,.

.Photochromic lenses are designed to darken on exposure to specific types of light of sufficient intensity, most commonly UV radiation. The lenses return to their clear state in the absence of activating light. Darkening typically takes about a minute, while lightening takes longer.

The photochromic process takes longer in colder weather and the lenses also become darker. The reverse is true at higher temps. Photochromic lenses that respond to UV won’t work when driving a vehicle because the windshield blocks most of the UV rays. They also won’t work in the shade or under heavy cloud cover.

Polarized lenses are designed for bright conditions where glare is a problem. They have a built-in laminated filter that allows only vertical light rays to pass through. The polarization almost totally blocks horizontal rays, thus eliminating reflected glare. Polarized lenses can block the visibility of many electronic displays. Many modern electronic displays rely on polarization.They can make slippery surfaces more difficult to see and can alter your depth perception.

The FAA recommends against the use of polarized lenses by pilots as they can impair visibility through an aircraft windscreen by enhancing striations in laminated materials and also mask the glint of light that reflects off shiny surfaces such as another aircraft’s wing or windscreen, which can reduce the time a pilot has to react in a “see-and-avoid” traffic situation.

Mirrored or flash coatings are also designed to reduce glare. They do make objects appear darker than they actually are, so lighter tints are often used to compensate for this. They don’t interfere with the visibility of electronic displays.

Other coatings that may be found on better sunglasses can include a hydrophobic coating to repel water, an anti-scratch coating, and an anti-fog coating for humid conditions or high-sweat activities.

Polycarbonate prescription lenses typically run about $150 with a scratch-resistant coating. If you have a stronger prescription and require high-index lenses, bifocal/multimodal/multifocal lenses, specialized coatings, or polarized or photochromic lenses, prepare to pay more.

Eyewear with interchangeable lenses can be useful where weight and space are at a premium. They allow you to tailor your eye protection to different activities and environments, while taking up minimal space.

Frames

Choosing the right frame is nearly as important as choosing the right lenses.

Frame materials that may be found on brand-name eyewear include a variety of metals, nylon, cellulose acetate, and castor-based polymer. The quality and design of the eyeglass frame are greater determinants of its durability than the material from which it’s made.

Metal continues to remain popular as a frame material and is easy to adjust. Although durability is an issue with many metal frames, some are very robust and nearly indestructible.

Nylon frames were introduced in the 1940s. Because of brittleness issues, manufacturers switched to blended nylons. Most sports and performance eyewear frames are made of blended nylons, which are lightweight and strong but not adjustable unless they have an internal adjustable wire core.

Cellulose acetate is a plant-based plastic popular on some high-end designer sunglasses. Acetate is lightweight and allows for greater color variations.

Castor-based polymer is another bio-based polymer that is seeing use for sunglasses’ frames. It’s a relatively new polymer that uses castor oil extracted from the seeds of the castor bean. It’s light, durable and features superior flexibility that can withstand repeated bending.

Impact rating, fit, and style are important. So too is compatibility with any other PPE that may be worn in conjunction with them and with any comms.

For optimal protection, the frames should fit snugly around the face in a wraparound style to prevent unfiltered sunlight from entering the eyes, as well as to provide additional coverage for protection from debris and impact and a wider peripheral view. And one must not neglect comfort, either.

The availability of foam inserts for the frame that can be installed when needed to provide the protection of a goggle can be a real plus. Some frames take it even further and are designed to be easily convertible from glasses to goggles.

All name-brand ballistic eyewear manufacturers offer Rx-capable models. Rx lenses may be built into the frame or into Rx inserts that attach to the frame. Regular eyeglasses should never be worn under your protective eyewear. Doing so puts you at a safety risk.

The US Army has adopted a cross-platform Universal Prescription Lens Carrier (UPLC) as the only lens carrier platform used by its Soldiers. The Army’s APEL indicates which of the approved eyewear is UPLC compatible.

Final Thoughts

Proper eye protection is essential. Only by becoming better informed consumers can we make the right purchasing decisions. You’ve only got one pair of eyes and you can’t replace them.

*The views and opinions expressed on this website are solely those of the original authors and contributors. These views and opinions do not necessarily represent those of Spotter Up Magazine, the administrative staff, and/or any/all contributors to this site.